|

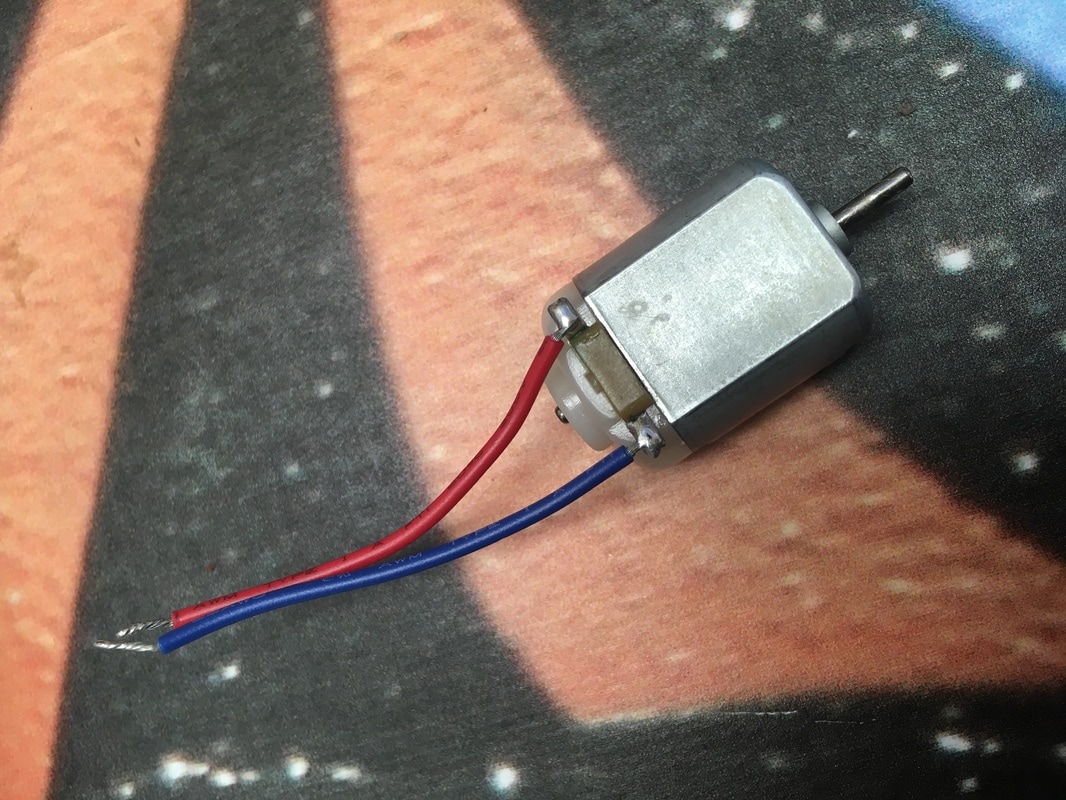

I had a few goals, based on the questions I posed in a recent blogpost. I wanted to find a way to power my PKE meter, I wanted to turn a beater from an old stand mixer into the pink part and add a blue LED to it, I wanted to move off my breadboard, I wanted to create a housing, and add a switch. Powering it turned out to be easy. I did some googling and found that while a 9-volt source is nto efficient, it will work. I knew I had a 9-volt battery adapter in my boxes of stuff. When I plugged in the external power source, the motor started right up, which is when I realized that the code was still on my Arduino. Yay! So then I set about trying to attach the mixer, and immediately ran into a problem: the beater was WAY too heavy for my little toy motor! At first I wondered if there was some way to get around that issue. Then, instead of facing it, I started working on the other issue: my toy motor had a smooth shaft. This itself presented two problems. First, I couldn't figure out how to attach anything to this surface, given the amount of spinning it is supposed to do. Second, I found myself reluctant to mention to the others in the room (read: men) that I didn't know how to stick anything onto the "smooth shaft" on my motor. And don't get me wrong—these were wonderful, supportive men. But in anticipation of either snickering or the fear that it would sound sexual/flirtatious, I said, "The motor thingy is smooth and I can't get stuff to stick to it. Do you have any ideas?" making me sound inept, but not sexual. This really makes me wonder how much language like this holds women back.  Once you get your motor spinning, take care when placing other objects onto its smooth shaft. I tried a number of ways to make attachments, and the most promising materials turned out to be the low fidelity stuff: craft sticks and super wikki stix. If you have never used wikki stix, think yarn-dipped-in-wax. They are posable, sticky, colorful, and cut-able. Pretty useful low-fi prototyping material. I also toyed with copper tape and blue LEDs. I ended up making three basic versions quickly, and did a bad job of documenting. The first was a compromise between the original and 2016 Ghostbusters version of the PKE meter: two craft sticks in a V shape, with LEDs at the end, and wrapped with a pink wikki stix to hold it together, and with some slightly complicated arrangements to create a parallel circuit with one battery. This looked pretty cool, but splayed when the motor began spinning. I quickly discovered that any version not connected at the top would do this, because physics works. I also realized I would also need a way to switch the battery on and off, and the copper tape is too fragile. Chris suggested using a wire, and this gave me the idea of adding pipe cleaners to my design. I moved to an all-wikki stix version, but realized right away this was too floppy. I then recalled (precedent!) that pipe cleaners are conductive. I snipped one into two pieces, stripped the fuzz off the ends, then used the wiki stixx to get everything into place, including a coin cell battery. This still seemed floppy, so I added a central craft stick. This was promising, but clearly still too heavy. I decided to start over with a lighter design, and repurposed one of the copper-tape lined craft sticks from my first prototype. This worked better, with the motor shaft stuck into a waxy ball made out of wikki stix (again with the temptation to call it a motor thingy). The smooth shaft was still an issue. I kept the design, but dug through my boxes of stuff to find another motor, and managed to find one with an attached gear. My other goal was to try to get my design off the breadboard. I talked to a computer scientist earlier in the day who seemed skeptical about my plan to use a piece of plastic and copper tape. Maybe reading this, you are skeptical as well? I looked up a schematic for how breadboards work, and set about reproducing the connections I needed, then began building a new prototype on this, that I thought matched my breadboard design. I transferred over my new motor to my copper tape version, and then plugged into my Arduino board. Success! In reflecting on my process, I realize I almost deliberately set myself up for failure with the copper tape prototype. I was pretty sure it would not work, and figured that failure would force me to learn why it failed. It didn't fail, and I am not sure I learned much, but I did notice much more about what is connected to what, and this is making me a bit curious about the various things that are a part of this design. Now that the breadbox is gone, some of the black box feel is gone. I can see what is connected to what. But I wonder if there is a better design for a teaching breadboard, that more clearly illustrates where the connections are?

I also note that I felt pretty sad when my beater turned out to be too heavy. Others had predicted it, but not connected its heaviness to the motor. At first, the beater seemed like such a fun choice. I was a little uncertain about how to put an LED on it, because I figured it would be conductive, but I had too little experience to predict that the heaviness would be an issue. This realization made me reframe the design. As I worked with the parts, I thought about their fragility, their temporary-ness on the breadboard. Because I am working in territory that is new to me, with materials that are unfamiliar, I find that I am not able to predict well what will work and what won't work. Each success brings a new horizon of problems and possibilities.

0 Comments

Leave a Reply. |

VanessaDesigner and researcher, researching designing. Archives

January 2018

Categories

All

|

RSS Feed

RSS Feed