|

Jim Henson has always been a major inspiration for me. One of my favorite pieces is thesteam pipes that he and his crew 'muppeted' while waiting to be on the tonight show. I take this as influential precedent as I think about the world. Do steam pipes have to be as they are? Does anything? And this makes me wonder about the coercive nature of some materials.

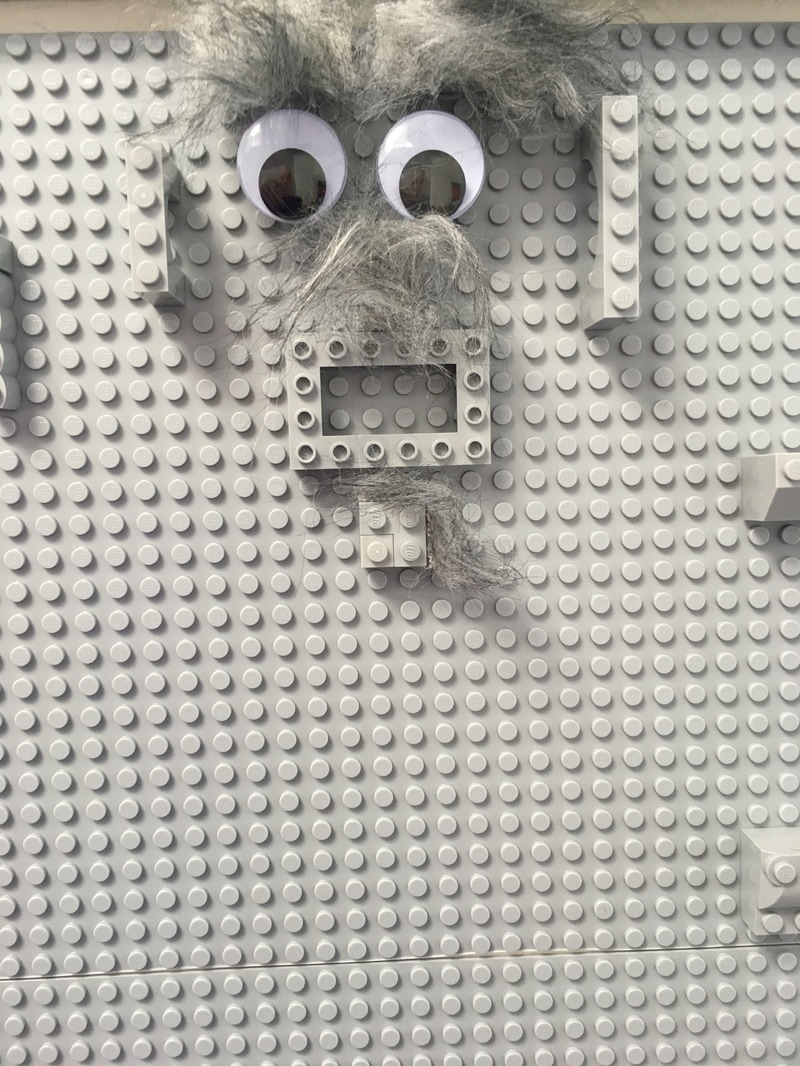

According to Donald Schön, design is a reflective conversation with materials [1]. Materiality is about the ways materials talk back to us when we design with them. This interests me in terms of exploring materials that are very familiar, very novel to me, and that change with use (called becoming materials [2]). We see that when designers work with new materials, they have trouble predicting where their design work will take them, until they have messed about with the materials [3]. A friend mentioned that there is a concept in Japanese landscape design that focuses on understanding what the materials want to do, and following that. This process, of being able to hear the voice of the landscape and be directed by it, is a skillful and high design concept. Part of the challenge is that human-made objects sometimes scream at rather than whisper to designers. As an example, consider LEGO blocks. They seem indestructibly rigid and they coercively tells us how to work with them. There is a felt need in the world—or at least among little kids who completed a 3D printing design challenge at our mini MakerFaire—to have blocks that change the direction of the studs. But I am more interested in a subversive approach. When designing, I try to look for the malleable edges in any given situation, for the things that can be flipped, for the need behind the surface need. And I try to be playful. That is why another favorite precedent is Sean Kelly's Project Runway dress that had to walk down a "rainway." A wonderful example of becoming materials, his plane-Jane white dress dyed itself as his model walked. Instead of treating the rain as a constraint, he made it part of the material.

So, how are we bringing this into our learning lab? First, we have this rather awkward column. It is load-bearing and made out of—as far as I can tell—adamantium. At the last minute, as I was ordering our supplies, I thought about creating installation spaces. Places to display our creations. I added some stainless steel pegboard, and a bunch of 15-inch LEGO baseplates. I thought we could glue them to a wall. But then, as more of our tech got installed, we ended up with a tangle of cords all draped around the column. I thought, 'Here is a design challenge for us." Which drew my attention to the column as an installation space. Clearly, screws are not meant to be added. I tried to remove the previously screwed in (at an angle) mini cork board strips. The screws were completely stripped. I decided to leave them. Cork board is handy. But I also decided to glue my baseplates to the column. The only problem: the column is ~19 inches wide, and the baseplates are 15 inches. My husband suggested I center them. But that would mean letting the LEGO coerce me. Turns out, if you line up the blocks along your cut line, one swipe with a basic craft blade (not a fancy one) is all it takes. That score line will snap so easily! I used a combo of liquid nails and E6000 glue.

Reactions. I want to record people's reactions as they see it for the first time. It goes a bit like this: "..." stopping mid sentence and staring. "Is that?!" "How did you get permiss-" I raise an eyebrow. As if anyone would have given permission for this. "I want one in my office!" Talking back to LEGO. So the next step, obviously, was to set about glueing googly eyes and muppet fur to LEGO blocks.

I don't know exactly how it will take shape, but I do know I want to integrate soft/fluffy/plush materials with the LEGO blocks.

References

0 Comments

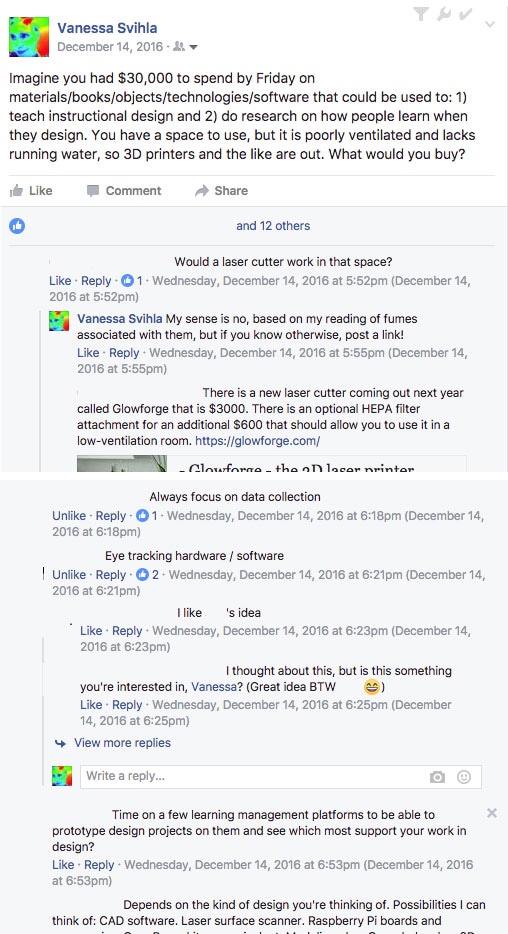

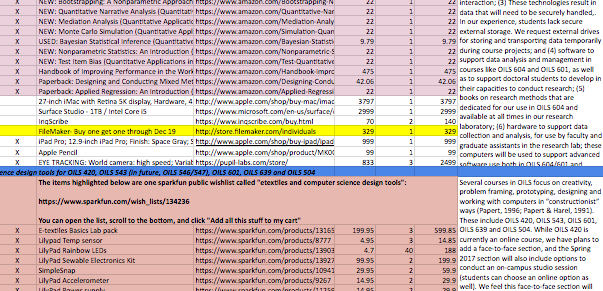

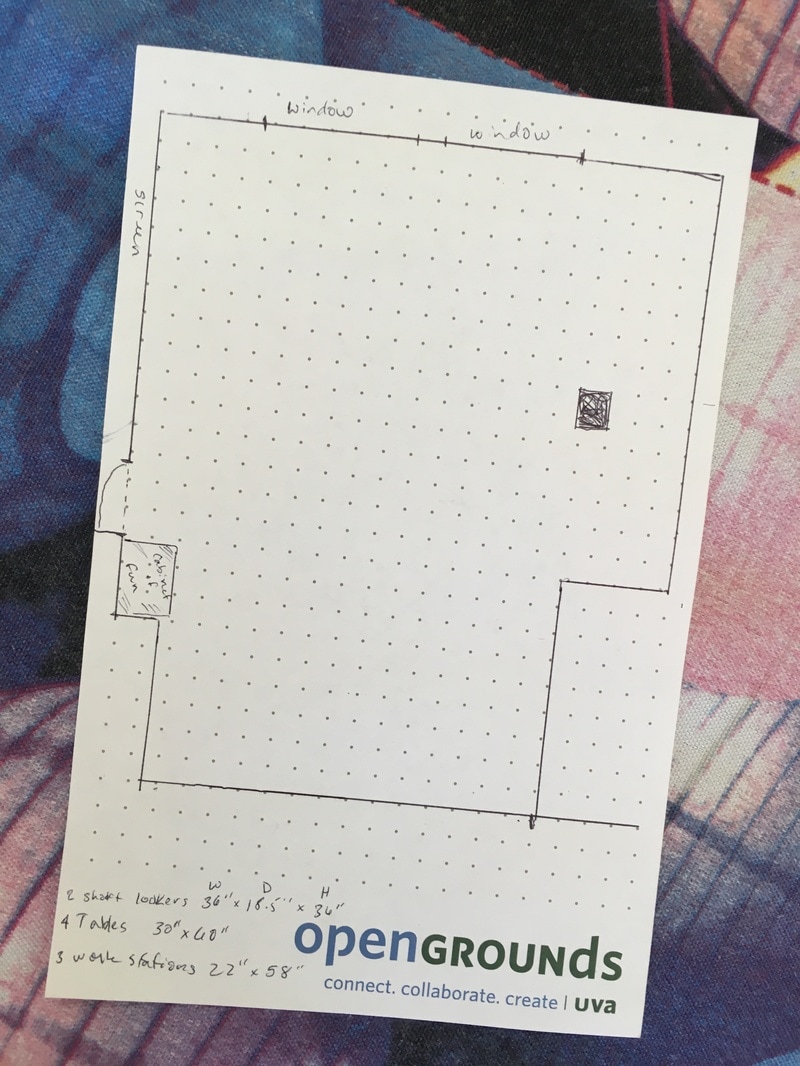

A FAB-ulous problem. In mid December 2016, we were given 2.5 days to allocate $30,000. It had to be used for our "OILS Commons" as it was then referred to. I proposed that we get a 3D printer, FabLab and maker stuff. Everyone seemed to be amenable to this idea. All that remained was to find $30,000 worth of stuff to purchase. In 2.5 days. A fabulous problem to have. A slow start. My colleagues came up with a few books they wanted. I listed a few odds and ends that seemed useful to have, In the space of 4 hours, we had allocated about 10% of the $30,000. So I emailed colleagues: "Pretend you had to spend $30,000 by Friday and you wanted to buy things that you could use in the study of learning. What would you buy? We may need to spend some funds, and I'd love to have time to plan and carefully select interesting technologies that we could then study, in terms of how they support learning. Instead, I am crowdsourcing. We have a learning lab but it has no possibility of high voltage, no special ventilation feasible, and no water available. Our learning lab has a ceiling camera (we call it the flying fish, as it is a birds eye view wide angle lens), and reconfigurable tables/chairs. I want to use this space to do studies of how people work with objects and sketching as they design. But the room is used by all OILS faculty, and could be used for a range of purposes. It is small, but works for small seminars of about 8-10 people. I was thinking about getting some basic maker space supplies, such as a 3D printer with an enclosure (like this: http://www.3dprintclean.com/). With the constraint of the room not being well ventilated and no water, I don't know how feasible 3D printers and laser cutters and so forth actually are. So, here is my question for you: What sorts of things/software, etc would you buy, that would let us study learning, especially with interesting tech? Also keep in mind that I have a smallish slush fund that could cover consumables in future." And I posted on facebook. Too many ideas. And we got lots of suggestions. And lots of links. I was budgeting for things I had never heard of based on the recommendations of trusted colleagues, friends of friends, and complete strangers. Pretty soon we were making tough decisions about what to NOT buy. Productive constraints. It was clear from the beginning that we could not change the space in meaningful ways. We could not add water or ventilation. The building is historic. And we had this awkward column near the back of the room to deal with. And the room is smallish, with floor to ceiling windows on one end and already had some furniture. And the room needed to retain its ability to support a range of activities, including classes in the evening.

|

VanessaDesigner and researcher, researching designing. Archives

January 2018

Categories

All

|

RSS Feed

RSS Feed